NC PROGRAM

OPTIMIZATION

Precise NC optimization for real machining results

Advanced, Cost Effective

NC Program Optimization Tool

MANUSsim Optimize analyzes the real NC program and optimizes it by accelerating and eliminating air cuts where possible, while also introducing variable cutting feedrates for optimal cutting conditions—achieving 10 to 40% machining time reduction

Increase Your Efficiency

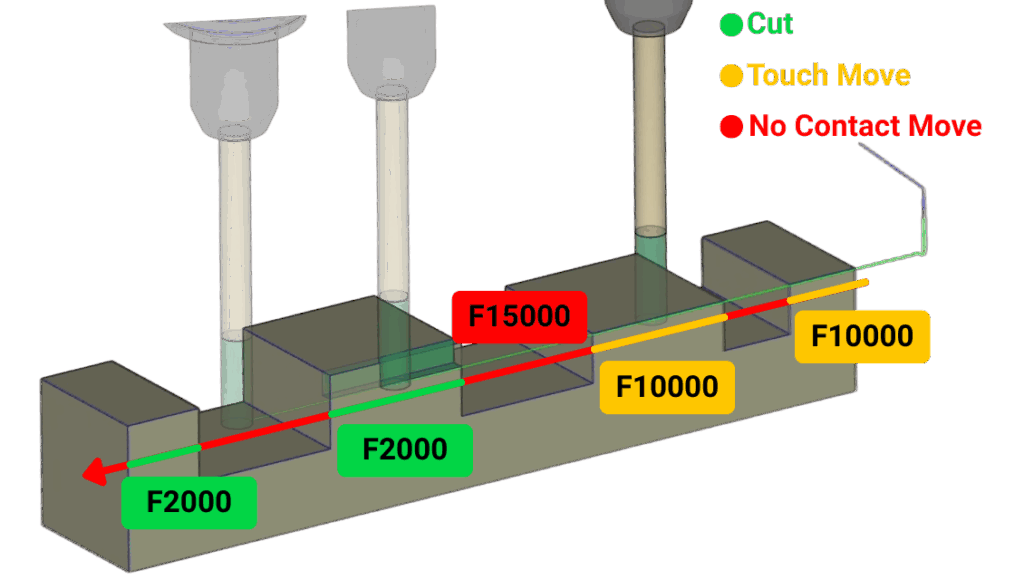

With 3 Different WaysAir Cut Feedrate Optimization

MANUSsim Optimize detects air cuts such as touch moves and no-contact moves directly from the real G-code and accelerates their feed rates automatically. You can freely assign different feedrates to touch moves and no-contact moves, exactly as you see fit. Same CAM. Same program. Shorter cycle time.

Air Cut Minimization

MANUSsim Optimize detects unnecessary home returns and long retracts in real G-code and safely reduces them to the minimum required distance above the surface. This reduction is performed by fully accounting for stock and fixture geometry, ensuring collision-free operation at all times.

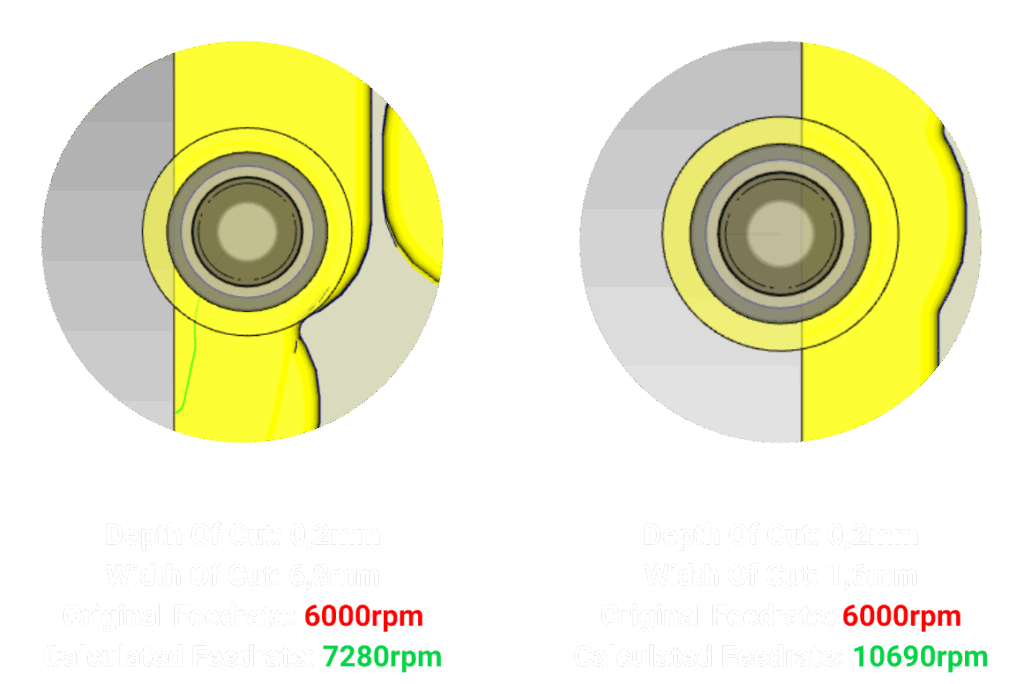

Cutting Feedrate Optimization

By simulating your NC programs we can accurately detect the chip geometry alongside depth and width of cut. Using this data we optimize your cutting feedrates by introducing variable feedrates achieving cycle time reductions typically in the range of 10% to 40%.

FAQ

No. MANUSsim optimize supports G-code generated by various CAM systems. As long as your output is standard or customized G-code, you can optimize it within MANUSsim optimize.

MANUSsim optimize works inside MANUSsim G-code simulation software. Since MANUSsim can analyze and simulate everything your CNC will do by simulating the atual G-code that works on your machine, It can detect every movement.

By using this data MANUSsim optimize finds all unnecesary movements and eliminates them or speeds them up. It can also detect the cutting feedrates and chip geometry during cutting. Thanks to this it can detect inneficient feedrates and defines varible feedrates depending on the chip geometry for optimal results. By making these adjustments inside your G-code it provides a more efficient, safer and faster machining process.

No. MANUSsim optimize reduces your machining time without ever sacrificing your prescision or quality.

As long as your CNC machine is already present on our simulation library or you can provide a 3D model of you CNC machine MANUSsim optimize can optimize your G-code. It also does support all the major NC controller on the market such as Fanuc, Heidenhain, Okuma OSP, Siemens Sinumeric, Fagor, Mazatrol, Fidia, Mitsubishi, Haas and Millplus.

No. MANUSsim optimize automatically detects inefficiencies and either gets rid of them or defines new feedrates values. However if you have advanced knowledge it also allows you to define values on your own according to you preferences.

Yes. You can access a free MANUSsim optimize demo license by downloading the MANUSsim demo via MANUSsim Editor. MANUSsim optimize demo is included automatically.

Please note that this demo is limited by NC line count, meaning only a portion of the NC program will be optimized. If you want a full optimization demo you can contact using the “Try Optimization On your Own Part” button.

Yes. With the “Try Optimization on Your Own Part” button, you can contact us for a demo.

Our team performs the optimization and sends you the optimized NC program, allowing you to directly compare cycle times and see the potential time savings.