What if you could complete CNC production 7 weeks ahead of schedule — without changing your tools, machines, or CAM settings?

It sounds unrealistic, right? But it’s already happening — and we’ve seen it firsthand.

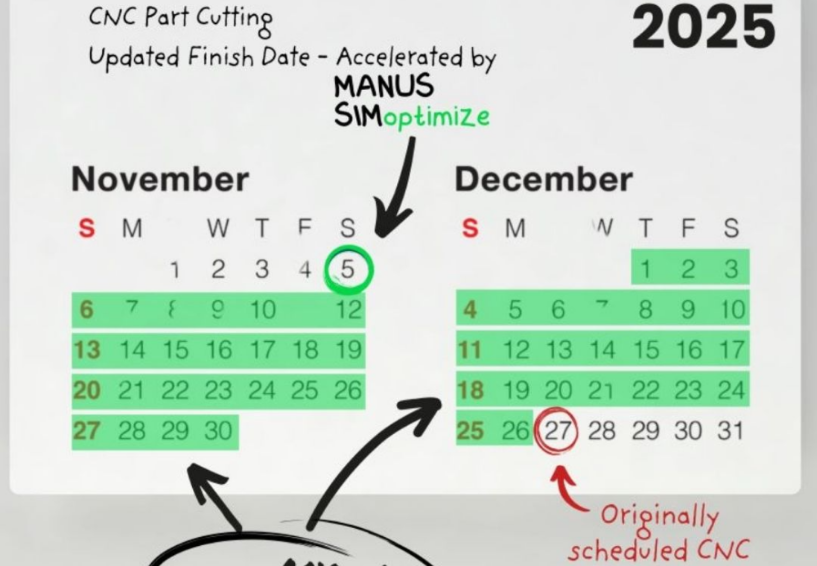

In a recent real-world case, our CNC part production was originally scheduled to be completed by December 27. After using #MANUSsimOptimize, the actual completion date was November 5 — an incredible 7-week head start, accomplished without rewriting a single line of CAM code.

So what made the difference? Smarter G-code simulation, validation, and optimization.

🚀 What We Achieved with MANUSsimOptimize:

Freed up valuable machine time — opened capacity for new jobs without adding machines

Reduced cycle time per part — achieved faster machining while maintaining part quality

Lowered production costs — less time, less energy, more efficiency

Boosted profit margins — got more done with the same resources

Offered more competitive quotes — without sacrificing profitability

Improved RFQ win rates — especially in price-sensitive tenders

Reduced operator overtime — better planning, less burnout

Improved on-time delivery — built-in flexibility and confidence

Maximized machine utilization — every spindle hour delivered more value

Minimized unplanned downtimes — thanks to full G-code validation that catches crashes, errors, and risky cuts (way beyond what CAM previews can detect)

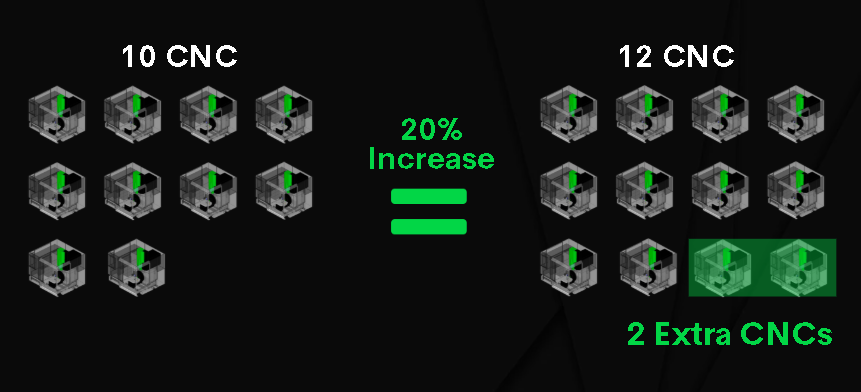

📊 A 20% Cycle Time Gain — What Does That Really Mean?

It means 5 CNC machines can now perform like 6.

In other words, you’ve added the power of a whole new CNC machine — without buying one.

That’s not just optimization. That’s strategic capacity expansion through intelligent code-level enhancement.

🛠️ No Risk. No Reprogramming. Just Smarter Results.

No change in your CAM software

No need to reprogram parts

No compromise in safety or quality

Just take the G-code you’re already using, simulate it with MANUSsim optimize, and let the software handle the validation and improvement — automatically.

🔍 Smarter G-code. Faster Machining. Safer Results.

#MANUSsimoptimize isn’t just another CAM add-on. It’s a new standard for CNC manufacturing.

Curious to learn more? Follow us for more real-world case studies and insights from the cutting edge of digital manufacturing.