Manufacturing is a race. Every second counts, and every inefficiency slows you down. Yet, many CNC shops still run with “ankle weights” — habits and processes that belong to the past.

The Cost of Old Habits

When G-codes are left unoptimized, even the most advanced CNC machines can’t perform at their best. The result?

⏳ Longer cycle times that eat into production capacity

💸 Higher cost per part

📉 Lost opportunities because of slower turnaround

⚠ Inconsistent cutting conditions leading to unpredictable results

It’s like investing in a race car but running it on flat tires.

The New Standard – MANUSsim optimize

G-code optimization is no longer optional — it’s the new standard for competitive manufacturing.

With MANUSsim optimize, you don’t need to touch your CAM workflow. Simply drop in your existing G-code and let the system do the work:

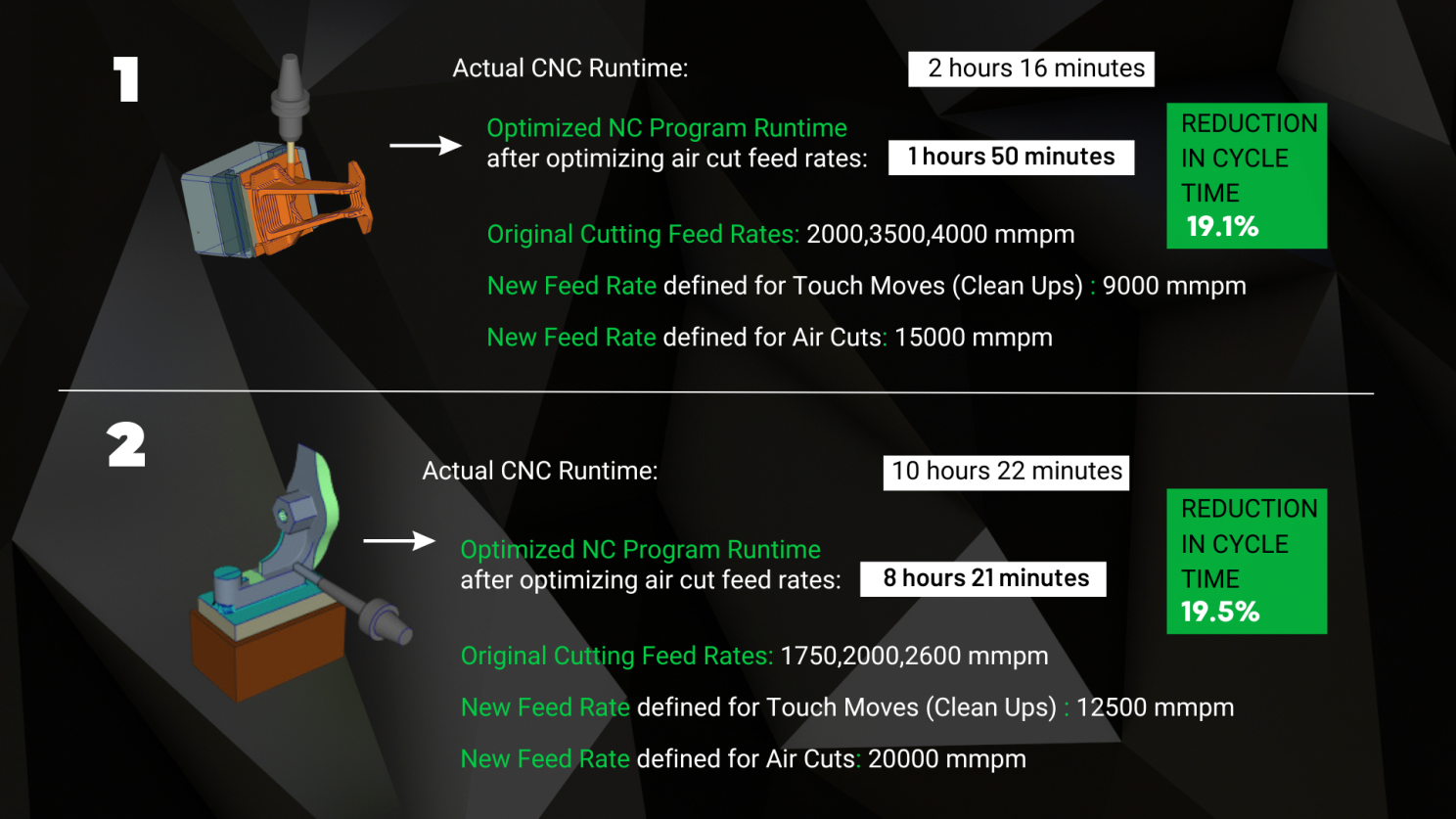

🚀 Faster cycle times — up to 40% time savings

📈 Lower production costs

🏆 More jobs won thanks to shorter lead times

🔄 Consistent, stable cutting conditions from start to finish

Why It Matters in 2025

Sending raw G-code straight to the machine might have been acceptable in 2005. But in 2025, it’s a missed opportunity. The manufacturing landscape is faster, leaner, and more competitive than ever.

G-code optimization transforms the pace of your production — removing inefficiencies, improving consistency, and letting your machines run at their true potential.

The race is on. The question is: are you running with the weight of old habits, or are you passing the baton to a faster, stronger, smarter way of manufacturing?