For two decades, one of the most common frustrations in the CNC industry has remained unchanged: “There are too many unnecessary moves or slow feeds in my G-code — and I can’t fix them.”

Despite all the progress in CAM software, the problem persists. CAM does its job in generating toolpaths, but it doesn’t always produce G-code that is truly optimized for your specific machine. The result? Programs often contain:

📉 Non-cutting moves that add nothing but cycle time

🔁 Inefficient retracts and repositioning (up-and-down steps that waste motion)

🐌 Feedrates that ignore cutting conditions such as chip geometry, depth of cut, and width of cut

Individually, these inefficiencies may seem small. But together, they act as silent killers of both productivity and profit margins. In today’s fast-paced manufacturing world, standing still is no longer an option.

The Hidden Cost of Inefficiency

Consider a machine tool running 24/7. Even a few seconds of wasted motion per cycle can add up to hours of lost machining time each week. Multiply that across multiple machines, and the financial impact becomes significant.

Manufacturers invest heavily in high-performance CNC machines, tooling, and CAM systems. Yet, if the G-code driving those machines is inefficient, much of that investment never reaches its full potential.

A Smarter Way Forward

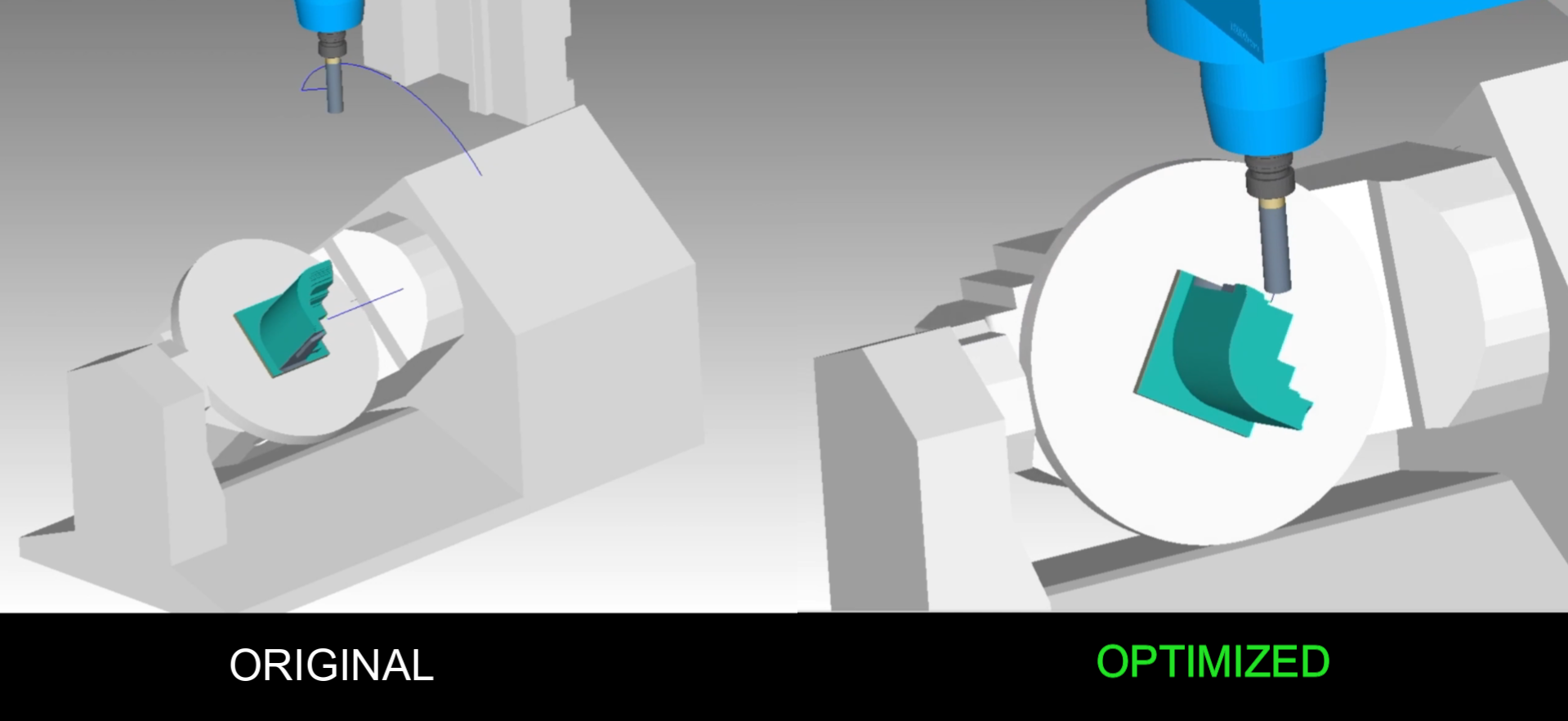

That’s where #MANUSsimOptimize steps in. Unlike traditional CAM-based adjustments, MANUSsim Optimize analyzes the actual G-code — line by line. It identifies inefficiencies and automatically generates a faster, safer, fully optimized version.

The best part? There’s no need to change your CAM setup. You keep your existing workflow, but unlock the hidden performance your hardware is already capable of.

Why It Matters

Shorter cycle times without sacrificing accuracy

Reduced machine wear and energy consumption

Higher productivity from the same equipment

A direct impact on profitability and competitiveness

You’ve already invested in the hardware. Now it’s time to unleash its full power.

🟢 Optimize your G-code. Reach higher.

Ready to See the Difference?

We’re offering a free trial optimization for the first part so you can experience the impact firsthand. Contact us for your free trial.