We are thrilled to introduce MANUSsim Editor, a highly anticipated addition to our MANUSsim product lineup. This innovative tool further amplifies the powerful capabilities of MANUSsim, which has already set a benchmark with its vast, detailed library of CNC digital twins. With the introduction of MANUSsim Editor, we are reaching a significant milestone, transforming how users approach CNC machine simulation and customization in a way that was previously unimaginable.

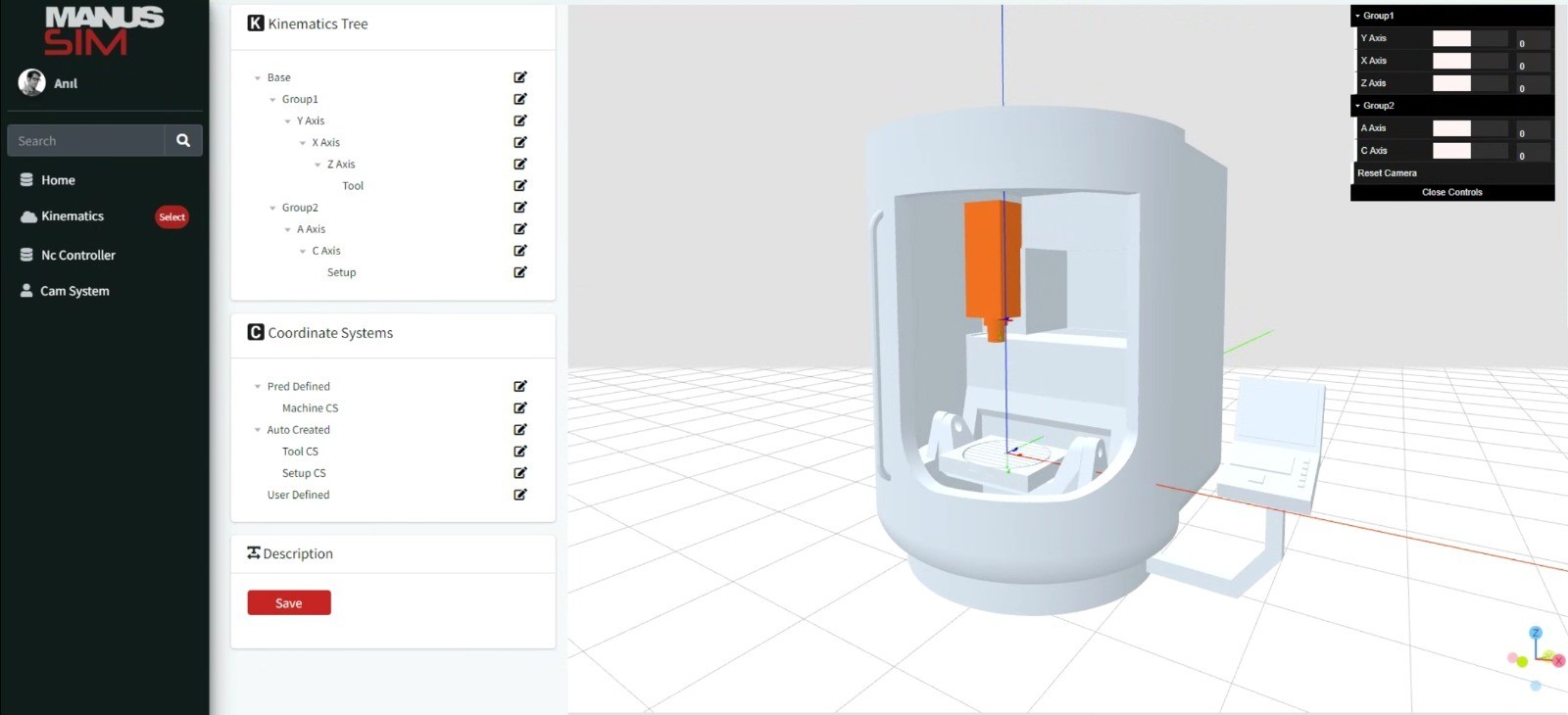

MANUSsim Editor empowers users to design, personalize, and adapt 3D models of CNC machines to match their unique operational environments. This new tool is about giving you control—not just to create custom models but to ensure that simulations reflect the exact conditions of your production line. With MANUSsim Editor, you can now fully tailor virtual machinery to achieve an unprecedented level of accuracy in your simulations, which directly impacts your efficiency, insight, and preparation for real-world machining.

Empowering Users with Unmatched Customization Options

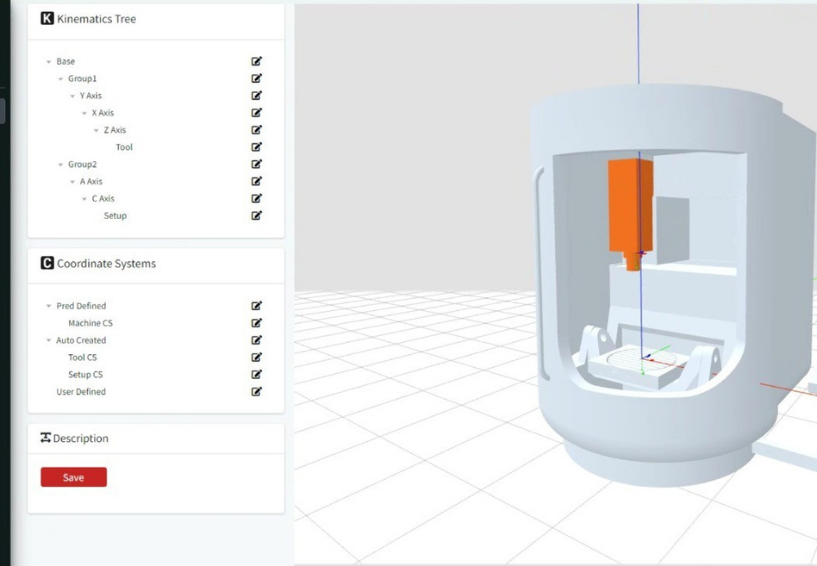

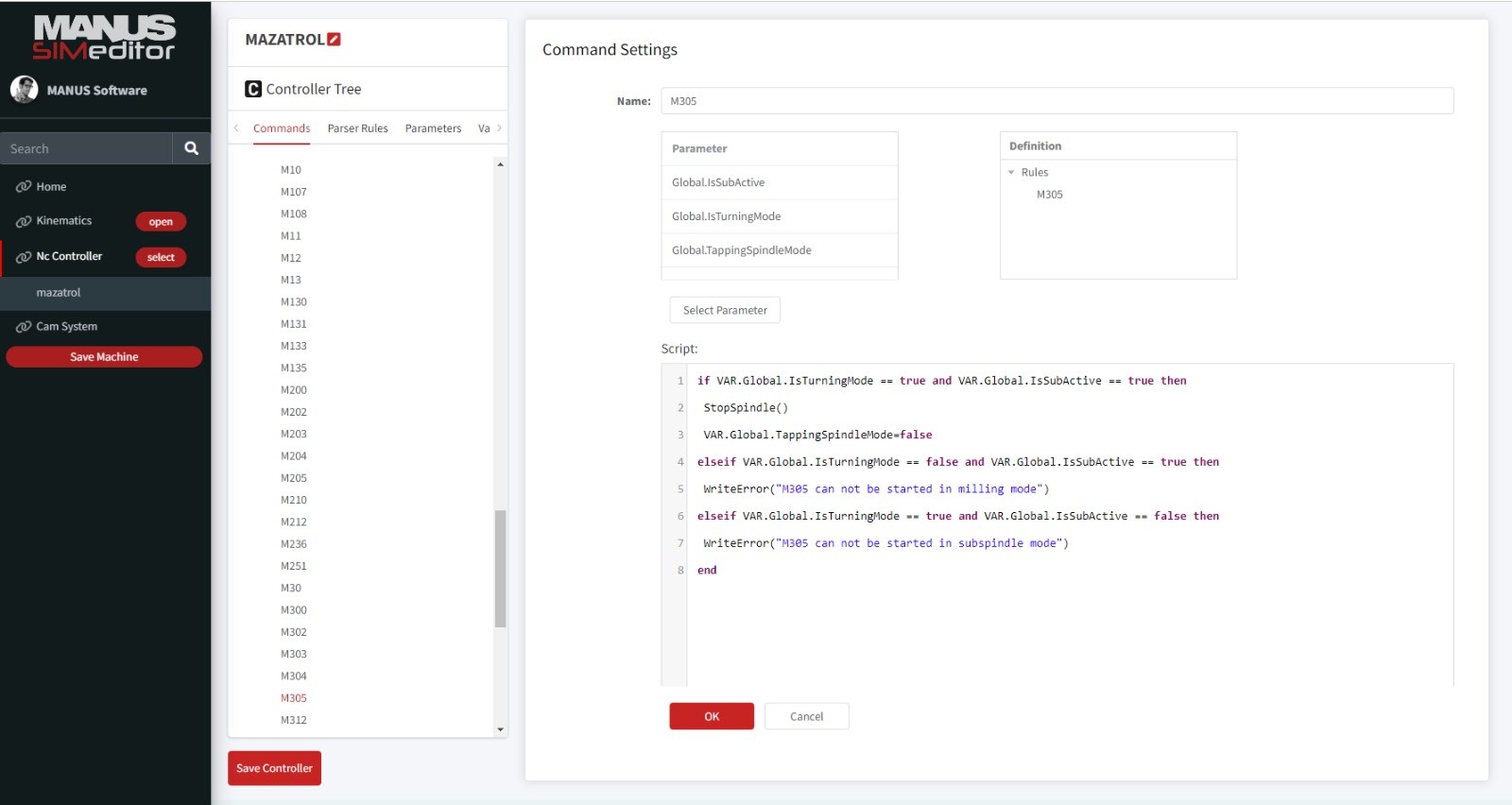

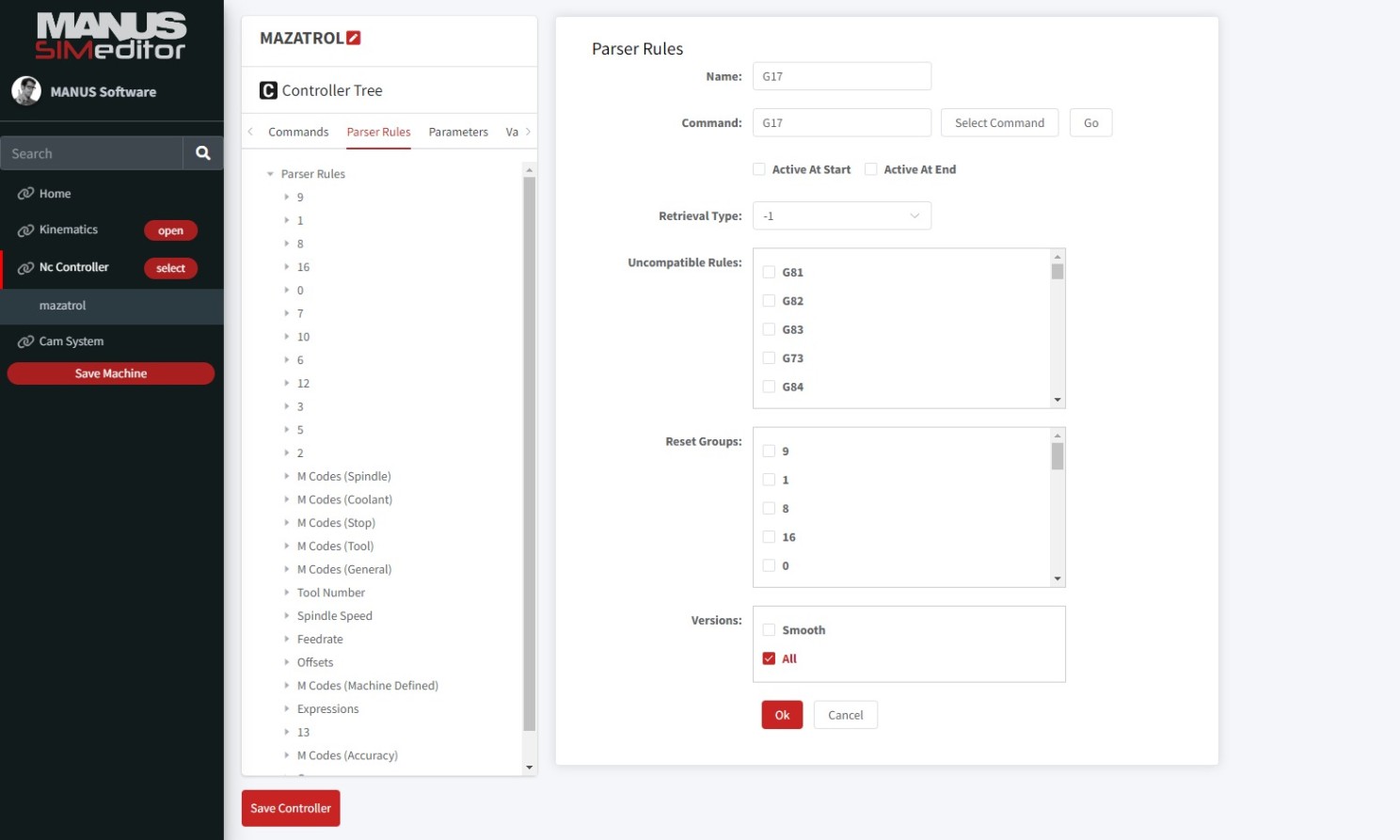

The customization capabilities of MANUSsim Editor are unrivaled, offering users complete flexibility in creating or refining CNC machine models down to the finest details. This feature set is particularly beneficial for engineers managing complex, multi-axis systems, as well as operators who work with highly specialized CNC configurations. MANUSsim Editor provides the capability to adjust every intricate detail of your CNC machine model, so your simulations go beyond what standard CNC libraries can offer. Whether you’re dealing with specific technical requirements, unique setups, or custom features, this tool ensures that every component is accounted for.

To clarify, MANUSsim Editor primarily focuses on customization rather than advanced simulation capabilities. By allowing users to tailor machine models to match specific shop floor setups, it enhances the accuracy and predictability of these setups but does not perform high-level simulations. MANUSsim, on the other hand, offers powerful simulation capabilities that provide deep operational insights and address complex machining scenarios directly. This distinction allows MANUSsim Editor to handle customized setups efficiently while MANUSsim performs the detailed simulations necessary for informed decision-making and productivity optimization on the shop floor.

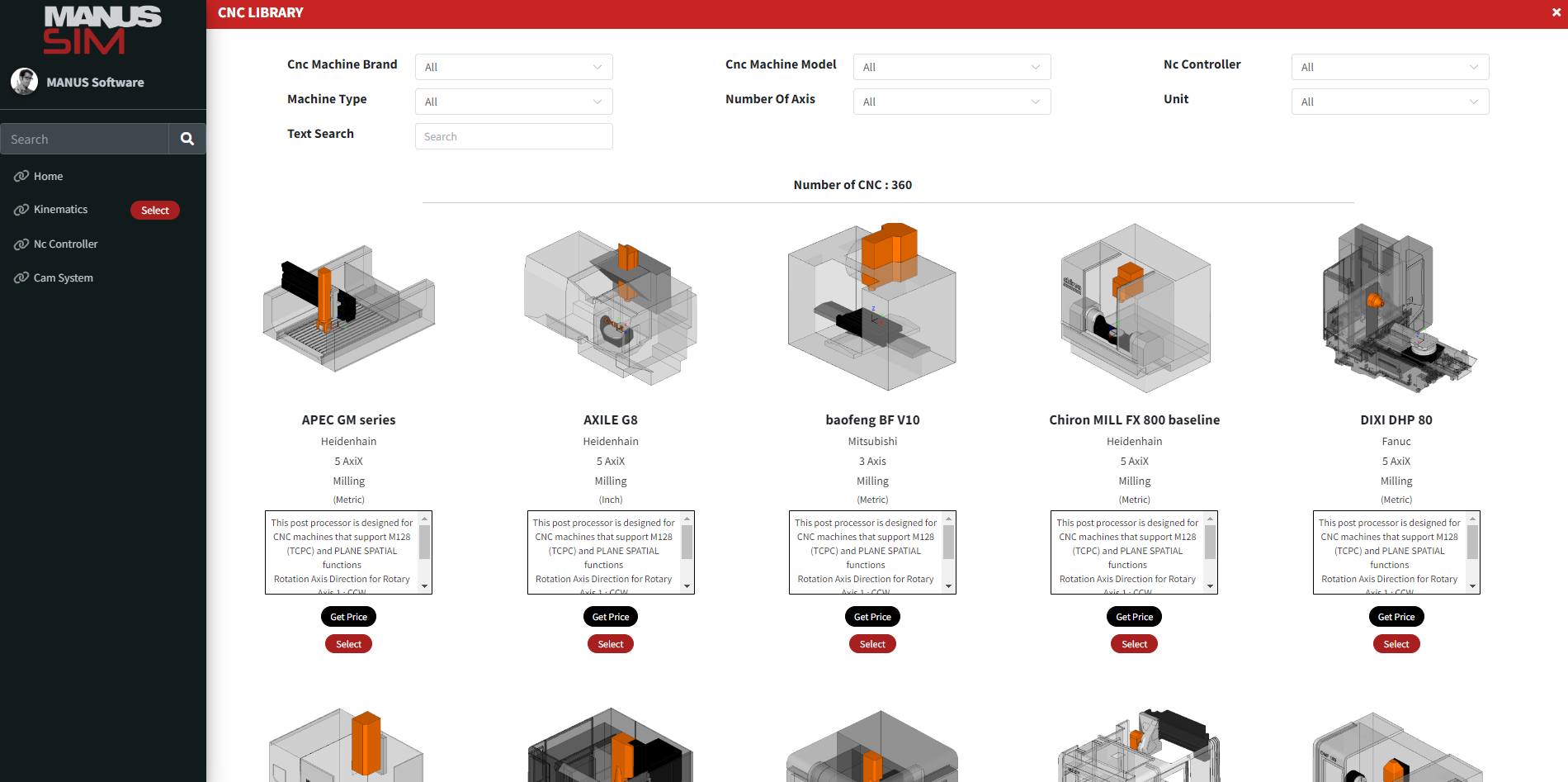

Enhancing User Flexibility with an Expanded CNC Library

In addition to offering cutting-edge customization features, MANUSsim Editor seamlessly integrates with our extensive CNC library, which currently houses over 300 pre-built CNC digital twins. This library gives users immediate access to an array of machine types, making it easier and faster to set up simulations. Whether you are working within standard industry frameworks or need specialized configurations, our library covers a broad range of applications, industries, and use cases.

But our commitment to providing versatile solutions doesn’t end here. As part of our ongoing development efforts, our team is continually expanding this library. Soon, users will be able to access an even broader selection of machines directly within MANUSsim Editor. By combining quick-start machine options with the ability to customize models from scratch, we’re giving you the best of both worlds—convenience and versatility—allowing you to get the most out of your simulations without spending excessive time on configuration.

Simulations Tailored to Specialized Needs

One of the most impactful aspects of MANUSsim Editor is its unique capability to simulate highly specialized or non-standard machines, a feature that is rarely found in other simulation software libraries. This capability is especially valuable for manufacturers in niche sectors or those handling highly customized projects. For these manufacturers, standard solutions are often inadequate as they do not provide an accurate representation of custom-built or extensively modified CNC equipment.

With MANUSsim Editor, users can model these machines down to the smallest details, ensuring that simulations capture the precise characteristics and behaviors of their equipment. This increased simulation accuracy leads to better-informed decision-making and provides a critical advantage in optimizing processes and reducing operational errors. By gaining an understanding of how these unique machines behave during various machining operations, users can make adjustments to optimize performance and improve efficiency, which is crucial for sectors where precision and customization are paramount.

Unlocking New Possibilities in CNC Simulation

The launch of MANUSsim Editor opens a new frontier for manufacturers looking to push the boundaries of CNC simulation. Whether you’re working with highly customized machinery or simply leveraging our expansive CNC library, MANUSsim Editor provides the flexibility, control, and accuracy you need to thrive in today’s competitive manufacturing landscape. As we continue to develop and enhance MANUSsim Editor, we encourage users to explore the transformative capabilities it brings to CNC simulation and digital twin technology.

This tool is built not just for today’s demands but also to anticipate the evolving needs of the industry. With a combination of detailed customization, precise accuracy, and a growing library of ready-to-use digital twins, MANUSsim Editor stands out as a game-changer for manufacturers of all sizes. As you adopt MANUSsim Editor, you’re not just investing in better simulation tools—you’re paving the way for a more efficient, optimized future in CNC machining.

Preparing for the MANUSsim Editor Launch

If you’re ready to elevate your CNC simulation capabilities, now is the time to prepare for the launch of MANUSsim Editor. Stay tuned for more updates and announcements, and get ready to unlock unparalleled opportunities in CNC simulation and optimization. With MANUSsim Editor, you’ll gain the power to design, simulate, and optimize your machinery like never before.