We are very excited about MANUSsim Editor, a groundbreaking addition to our CNC software solution range. This cutting-edge tool revolutionizes the way CNC machine simulations are created and customized, empowering users with unprecedented control over their digital twin environments. MANUSsim Editor takes customization to the next level, enabling users to tailor virtual machinery to match their real CNC machine with accuracy.

Unparalleled Customization for CNC Simulations

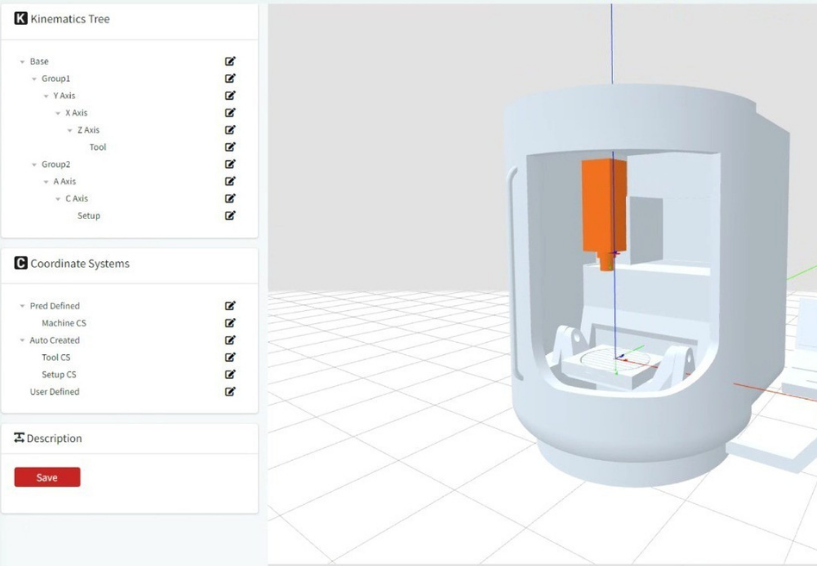

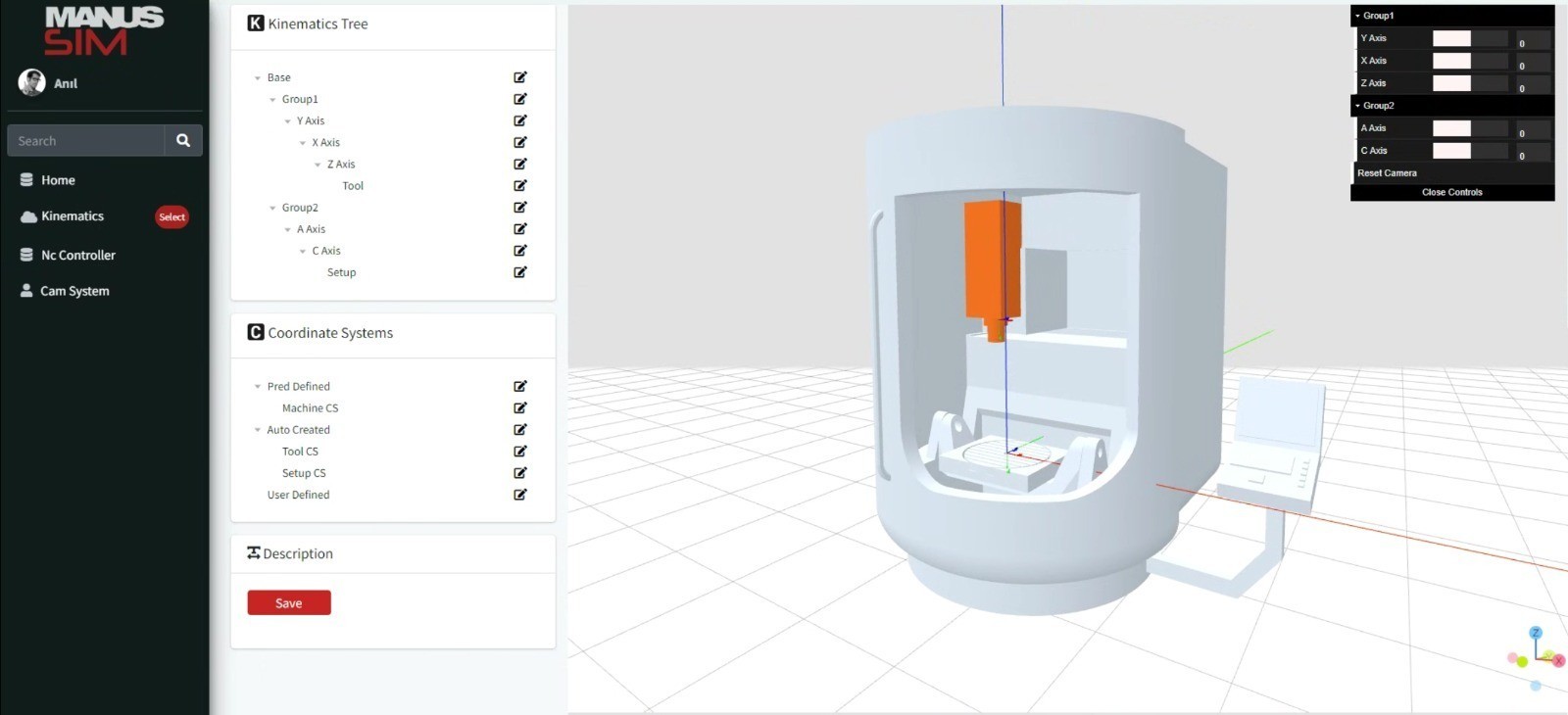

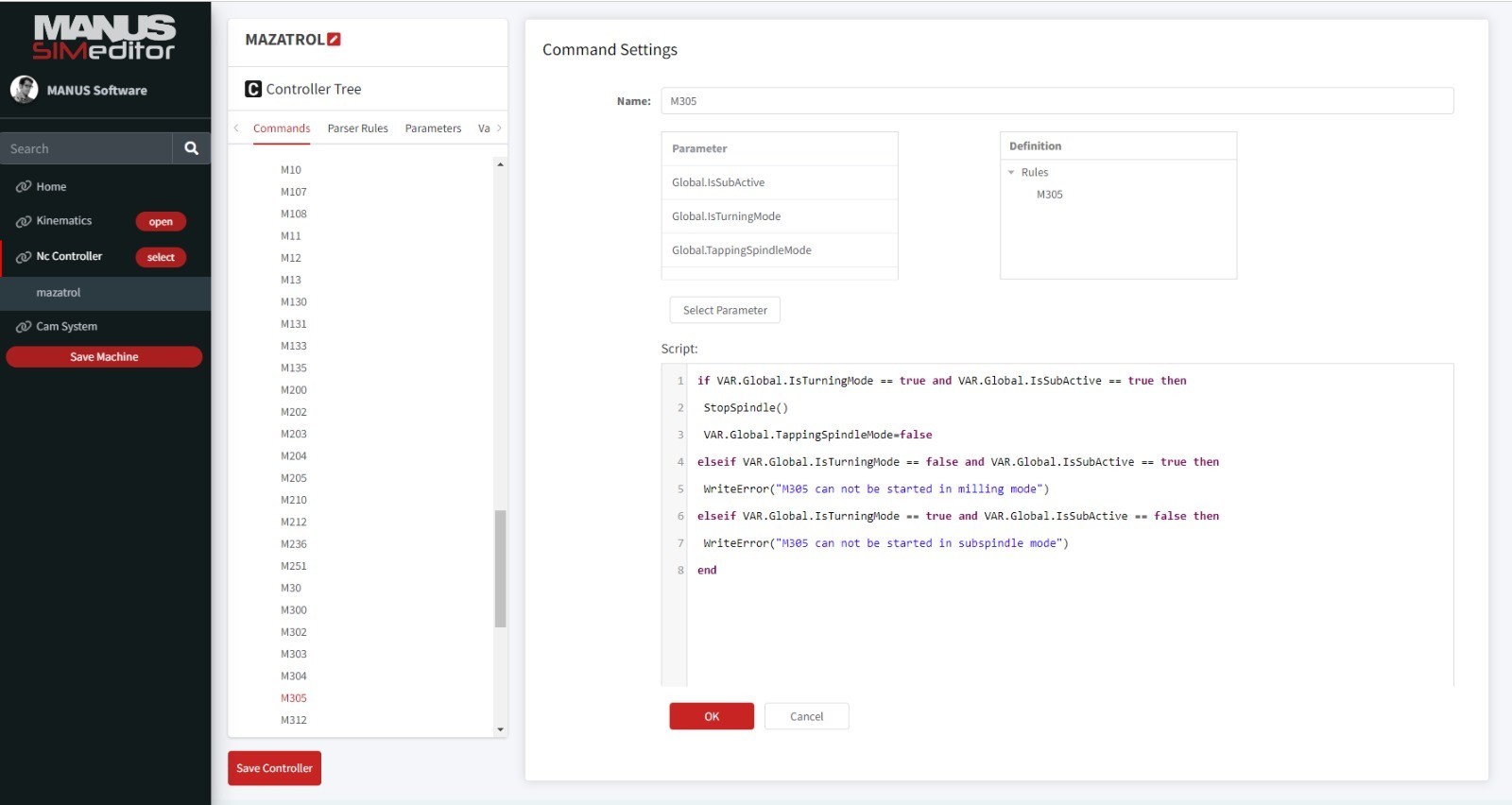

With MANUSsim Editor, users can design, modify, and adapt 3D CNC machine models to reflect their specific operational setups. Whether it’s fine-tuning components, replicating unique machine configurations, or ensuring a perfect match between virtual and physical environments, this tool puts complete customization at your fingertips. Engineers working with complex, multi-axis systems and operators handling specialized CNC setups will find MANUSsim Editor indispensable in refining their CNC simulation models beyond conventional pre-built libraries.

It’s important to highlight that MANUSsim Editor focuses on customization rather than high-level simulation capabilities. While it enhances the precision of machine models for better predictability and alignment with production processes, full-scale G-code simulations and operational insights remain the domain of MANUSsim. This distinction allows manufacturers to craft highly detailed digital twins while leveraging MANUSsim’s powerful G-code CNC simulation for machining analysis.

Expanding CNC Possibilities with a Growing Library

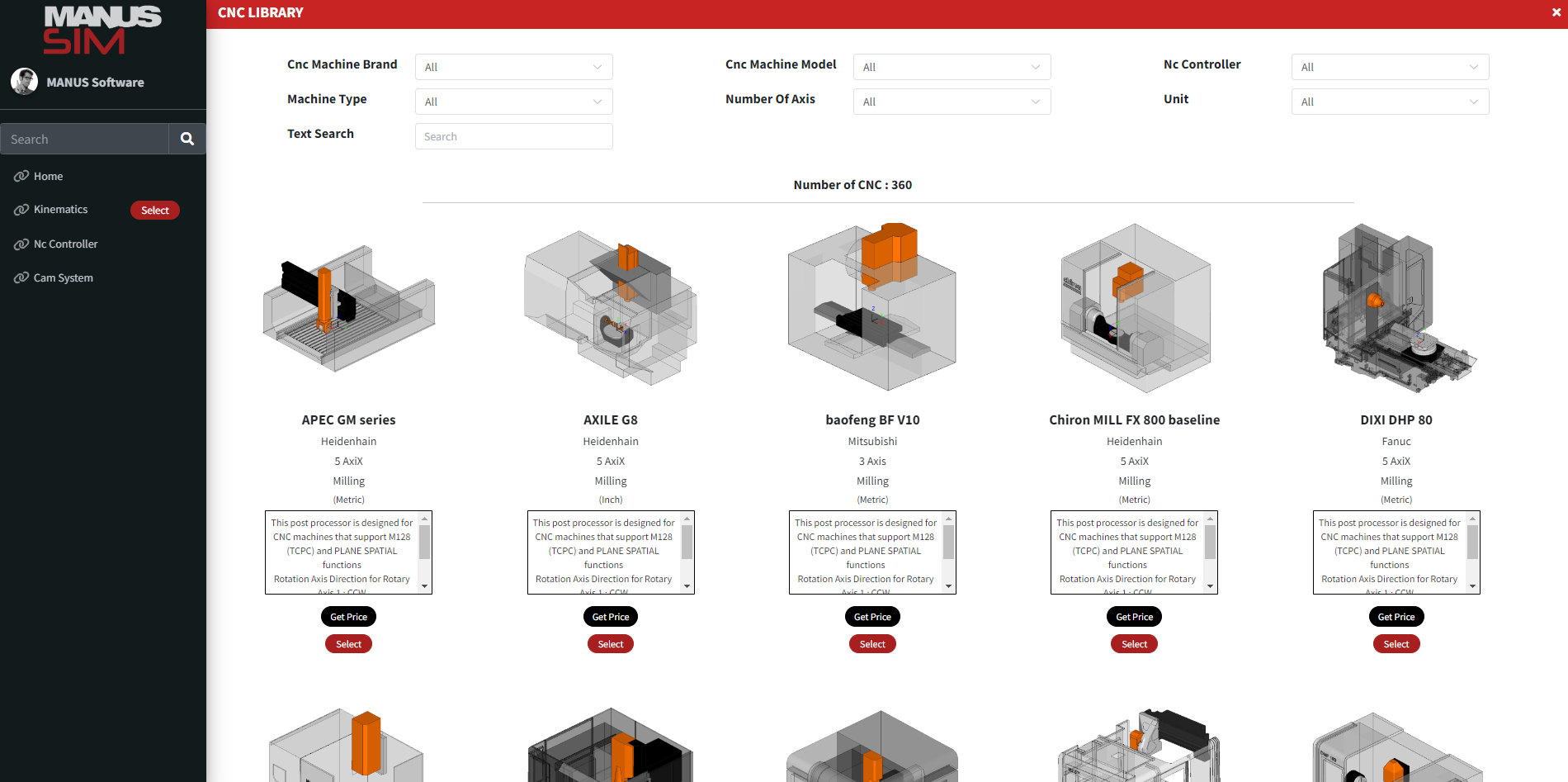

A key strength of MANUSsim Editor lies in its seamless integration with our expansive CNC machine tool library, which features over 300 pre-built machine models. This extensive collection provides a strong foundation for users to quickly set up and refine their simulations, covering a diverse range of industries and applications.

But we’re not stopping there. Our development team is continuously expanding the CNC library, ensuring users have access to an ever-growing selection of machines. Whether you require a rapid setup using existing models or wish to craft a fully customized machine from scratch, MANUSsim Editor offers both convenience and flexibility to streamline your workflow.

Catering to Specialized and Non-Standard CNC Machines

Manufacturers operating with highly specialized or custom-built CNC machines often struggle with standard CNC simulation solutions that fail to capture the nuances of their equipment. MANUSsim Editor bridges this gap, allowing users to model intricate machine details that reflect real-world performance more accurately than ever before.

By incorporating these refinements into their digital workflows, users gain better insights into machine behavior, reducing errors and improving efficiency. Whether it’s for aerospace, medical, or high-precision engineering applications, MANUSsim Editor ensures that no detail is overlooked in the pursuit of operational excellence.

Pioneering the Future of CNC Simulation

The introduction of MANUSsim Editor marks a significant leap forward in CNC G-code simulation technology. By offering deep customization options alongside an expansive CNC library, it provides manufacturers with the tools needed to fine-tune their processes and enhance simulation accuracy.

As we continue to develop and refine this tool, we invite users to explore the transformative capabilities it brings to CNC simulation. MANUSsim Editor is not just an enhancement—it’s a shift in how CNC machines are digitally represented, making advanced customization accessible to every manufacturer.

Get Ready to Experience MANUSsim Editor

Now is the time to elevate your CNC simulation capabilities. Stay tuned for upcoming updates and announcements as we roll out MANUSsim Editor, the tool that will redefine how manufacturers approach CNC machine customization. With MANUSsim Editor, precision, efficiency, and optimization are just a few clicks away.