At MANUS Software, we believe that CNC simulation should do more than just prevent crashes. It should make your manufacturing process smarter, faster, and more efficient.

And now — it does.

Introducing: MANUSsim Optimize

A game-changing advancement in true G-code simulation and optimization.

With a single click, you can now simulate and optimize all cutting moves and air cuts simultaneously — no additional configuration needed.

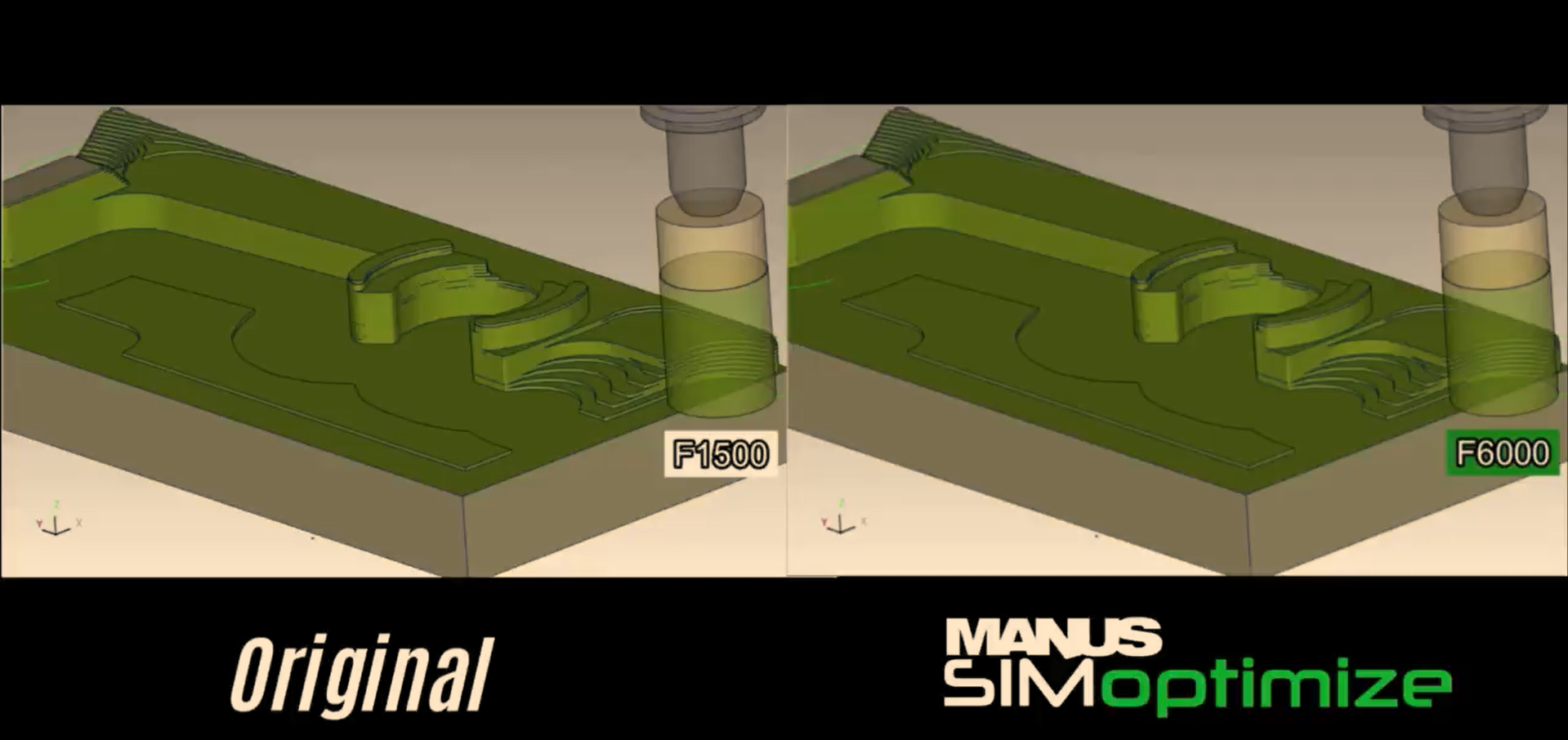

Real Results:

Our most recent tests showed a 32.7% reduction in machining time — without touching your CAM settings or post processors.

Yes, you read that right:

No changes to CAM settings

No post-processor modifications

No cutting tool or material definitions required

Just run the simulation — and let MANUSsim Optimize do the rest.

How It Works:

While you’re verifying the motion visually, MANUSsim Optimize automatically:

Detects all rapid (non-cutting) moves and accelerates their feed rates

Recalculates cutting feedrates based on real geometric parameters — like depth of cut and width of cut

Ensures smooth and safe starting conditions, especially during the first few runs

Why It Stands Out:

Lightning-fast optimization

Reliable and robust logic

Easy-to-use interface

Seamless setup

no complex configurations needed

Ready for Real-World Use:

Compatible with both 3-axis and 5-axis milling machines, Works with major CAM systems: Mastercam, NX, Fusion 360, PowerMill, CATIA, and more, Supports all controllers: Fanuc, Siemens, Heidenhain, Mitsubishi, Mazatrol… Runs on any machine brand: Haas, Mazak, DMG Mori, Makino, Doosan, and beyond

Ready to see simulation become your productivity engine? With MANUSsim Optimize, simulation is no longer just a safety net — it’s your competitive edge.