In the world of CNC manufacturing, simulation is no longer a luxury—it’s a necessity. But not all simulations are built the same. There’s a significant difference between what you see in CAM software and what actually happens on your CNC machine. And this gap is exactly where MANUSsim steps in..

Simulation Isn’t Just About Visualization

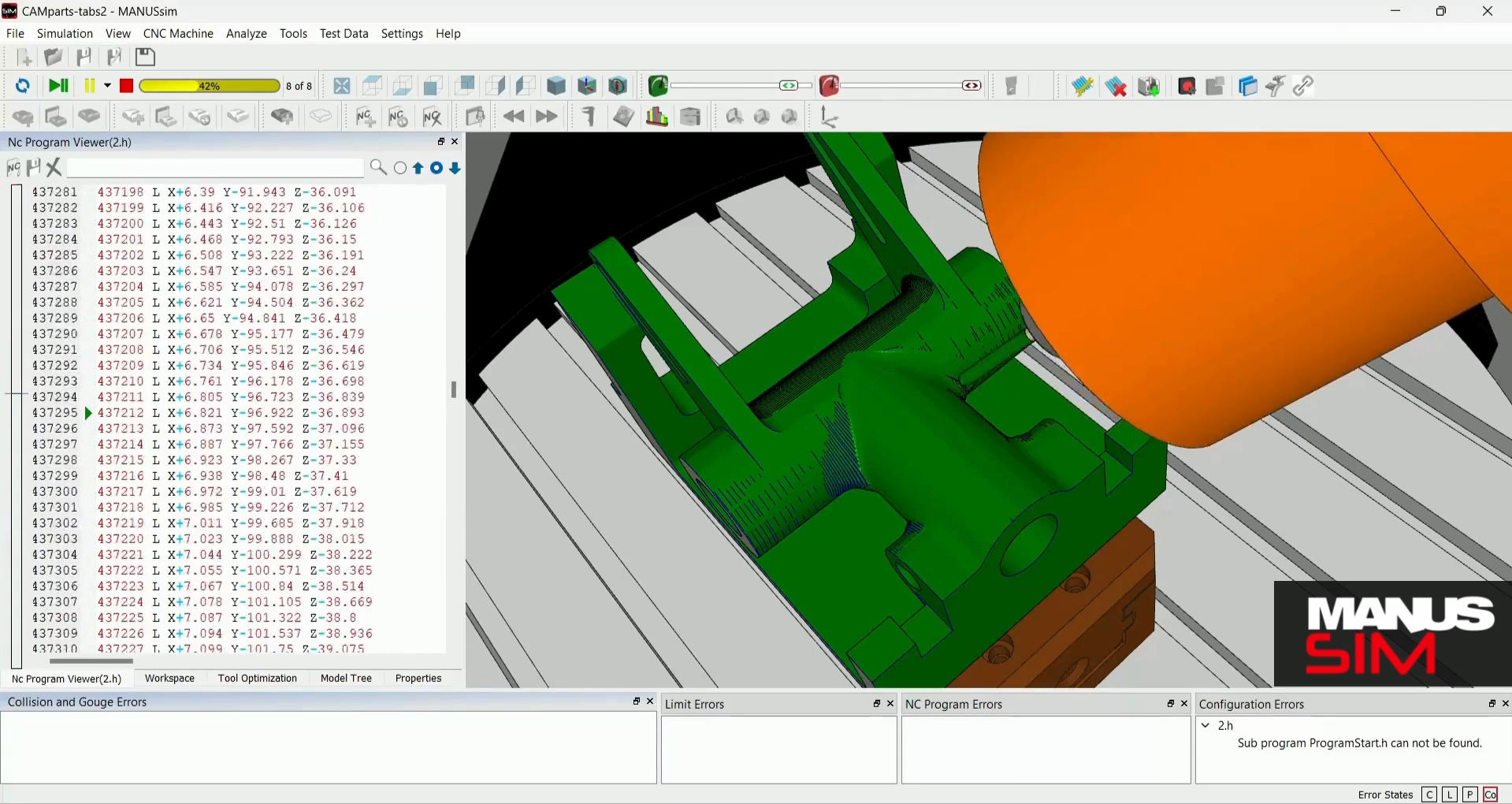

In many shops, CAM simulations are treated as the final word. But in reality, what you see in the CAM environment isn’t necessarily what your CNC machine will execute. Why? Because most CAM simulations don’t simulate the real G code—they visualize toolpaths before post-processing, and that leaves room for costly surprises.

That’s a huge risk in high-precision or high-complexity jobs.

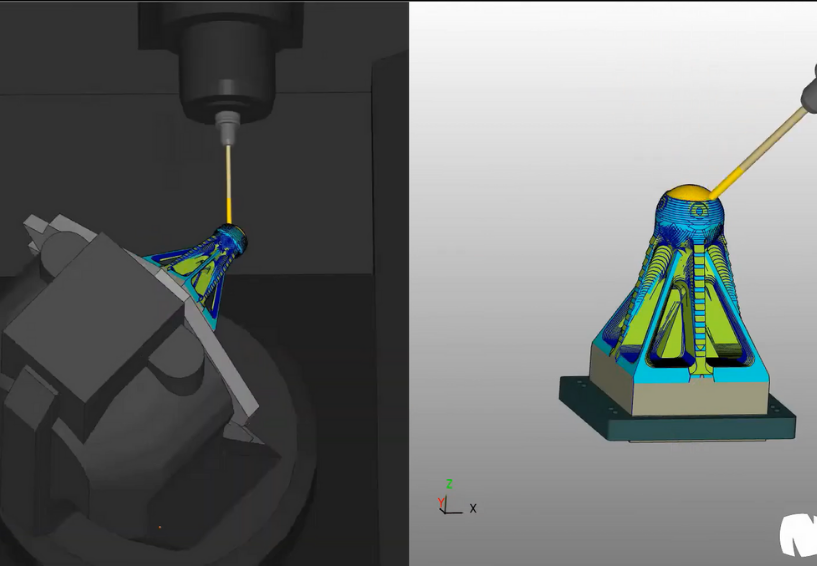

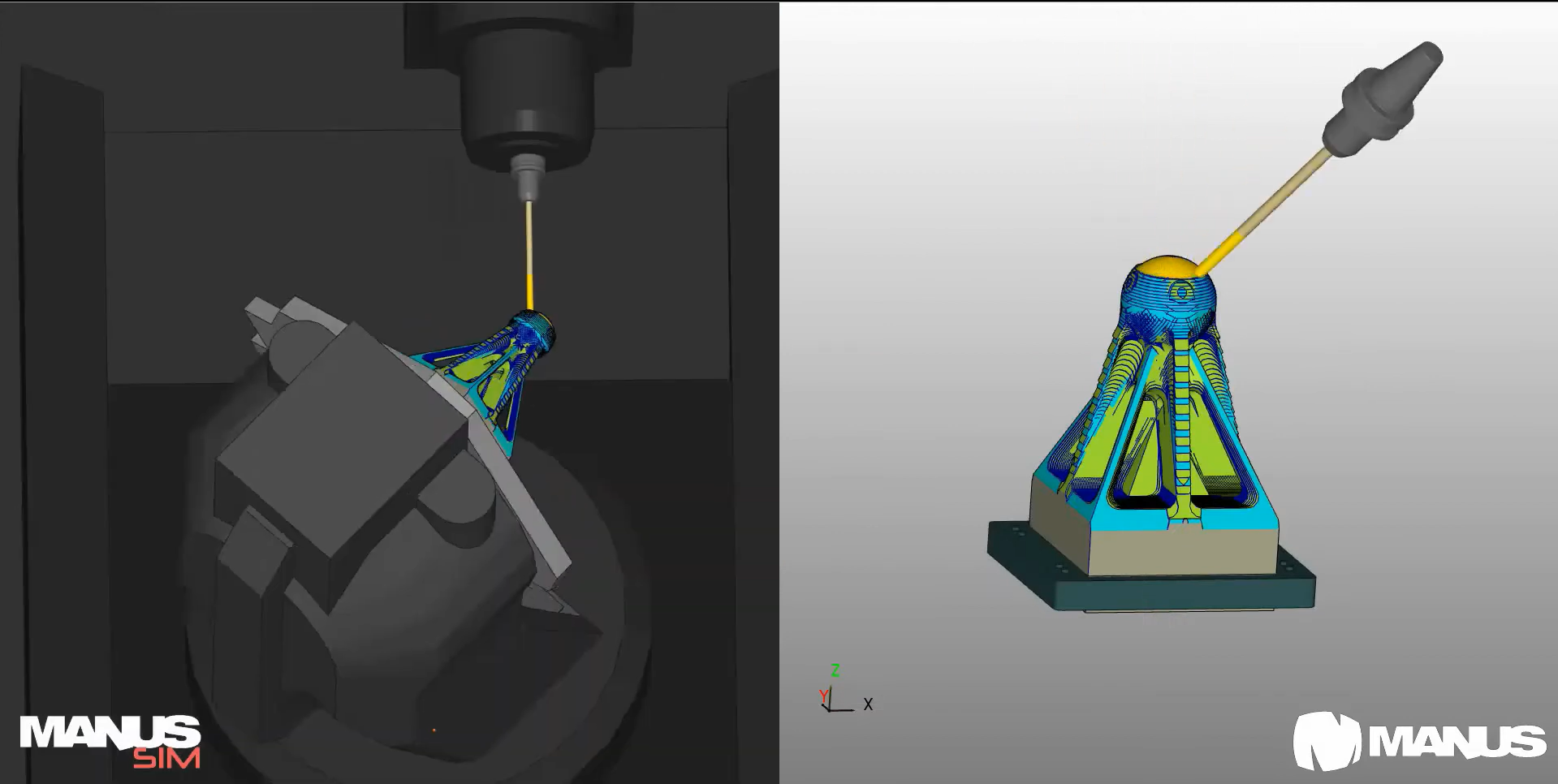

Enter MANUSsim: Simulation That Mirrors Reality

MANUSsim doesn’t guess. It knows. It reads and simulates the actual G code your machine will use—including macros, machine logic, subprograms, and even custom M codes.

This means what you see on screen is exactly what your machine will do. No guesswork. No surprises.

Future-Proof and Flexible

Unlike CAM-based simulations, MANUSsim works with all the major CAM software in the market. Whether your team uses multiple CAMs or transitions between them over time, your simulation environment stays consistent, accurate, and reliable.

This flexibility is especially valuable for large-scale operations and growing teams.

What’s Coming Next? MANUSsim Editor

To take things even further, we’re launching #MANUSsimEditor, a new platform that makes it easier than ever to:

Access our expanding CNC machine library

Customize your own machine setup for simulation

Tailor your environment for simple 3-axis jobs or complex multi-turret mill-turn systems

You’ll get full control and flexibility.

Whether you’re a CAM programmer, a CNC operator, or a manufacturing engineer, it’s time to rethink what simulation really means.