“Once upon a time…” — it might be how stories begin, but in real-world CNC machining, fairy tales rarely end well.

Despite growing complexity in manufacturing, many machine shops still rely heavily on CAM-driven toolpath simulations. These simulations are based on ideal scenarios — they visualize tool movement before post-processing, often giving a false sense of security. The problem? They don’t simulate the actual G-code your machine will run.

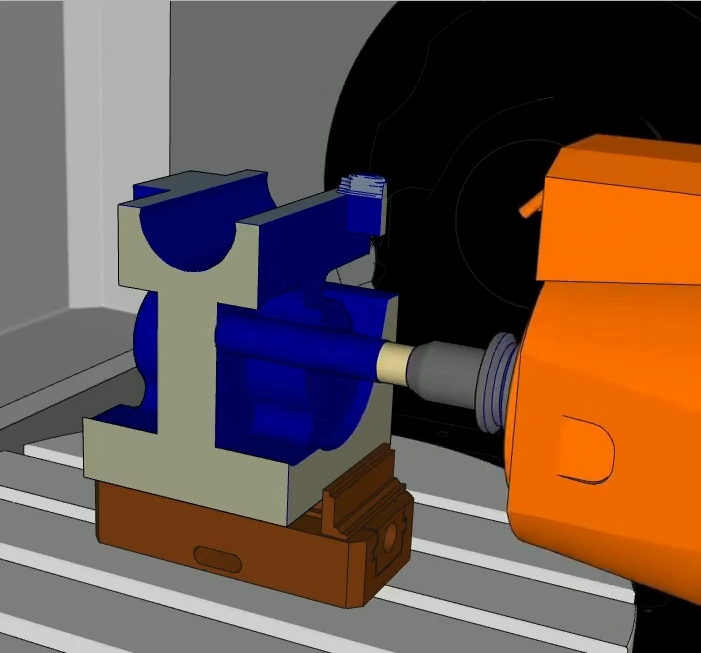

When the Story Turns into a Nightmare

The comfort of CAM simulation can come at a cost:

🔧 A missing retract line…

💥 An unnoticed collision…

🕒 Unexpected rework…

💸 Costly scrap and downtime…

And most of these crashes? They don’t happen during exotic 5-axis aerospace parts. They happen during the “simple jobs” — during tool changes, indexing, and transitions between operations. Exactly the parts most CAM simulations don’t verify.

Simulation vs. Wishful Thinking

Here’s the bottom line:

✅ If it’s not checking the actual NC program line-by-line, it’s not protecting your machine.

✅ If it’s not verifying real feed rates, axis limits, tool motions, collisions, and gouges — it’s not a simulation. It’s just a nice-looking animation.

Real Confidence Comes From Real G-Code

To avoid turning a simple job into an expensive mistake, machinists and programmers need G-code-driven simulation like #MANUSsim. It’s the only way to:

Detect real errors before they hit the shop floor

Optimize cycles based on what the machine actually sees

Ensure safer, faster, and more reliable production

Don’t settle for comfort — demand accuracy.

Because in CNC machining, only the real thing delivers real-world results.