In manufacturing, resistance to change isn’t new. There’s always been a loud chorus of voices declaring, “CAM simulation is enough.” “Real machinists don’t need simulation.” “We’ve always done it this way.”

Meanwhile, decisions that shape production are often made behind closed doors — where risks are minimized not through better validation, but through plausible deniability.

But let’s be honest: Running toolpath previews is not the same as verifying post-processed G-code.

Just as you wouldn’t trust a GPS without checking the road, relying solely on CAM simulation means overlooking a critical layer of production safety. And when things go wrong? Without G-code simulation, there’s always someone else to blame.

So why do some still hesitate?

Because introducing G-code-level simulation requires ownership.

Because changing old habits takes effort.

Because it’s easier to assume than confirm.

But with today’s complexity — tighter tolerances, higher speeds, shorter lead times — that mindset no longer works.

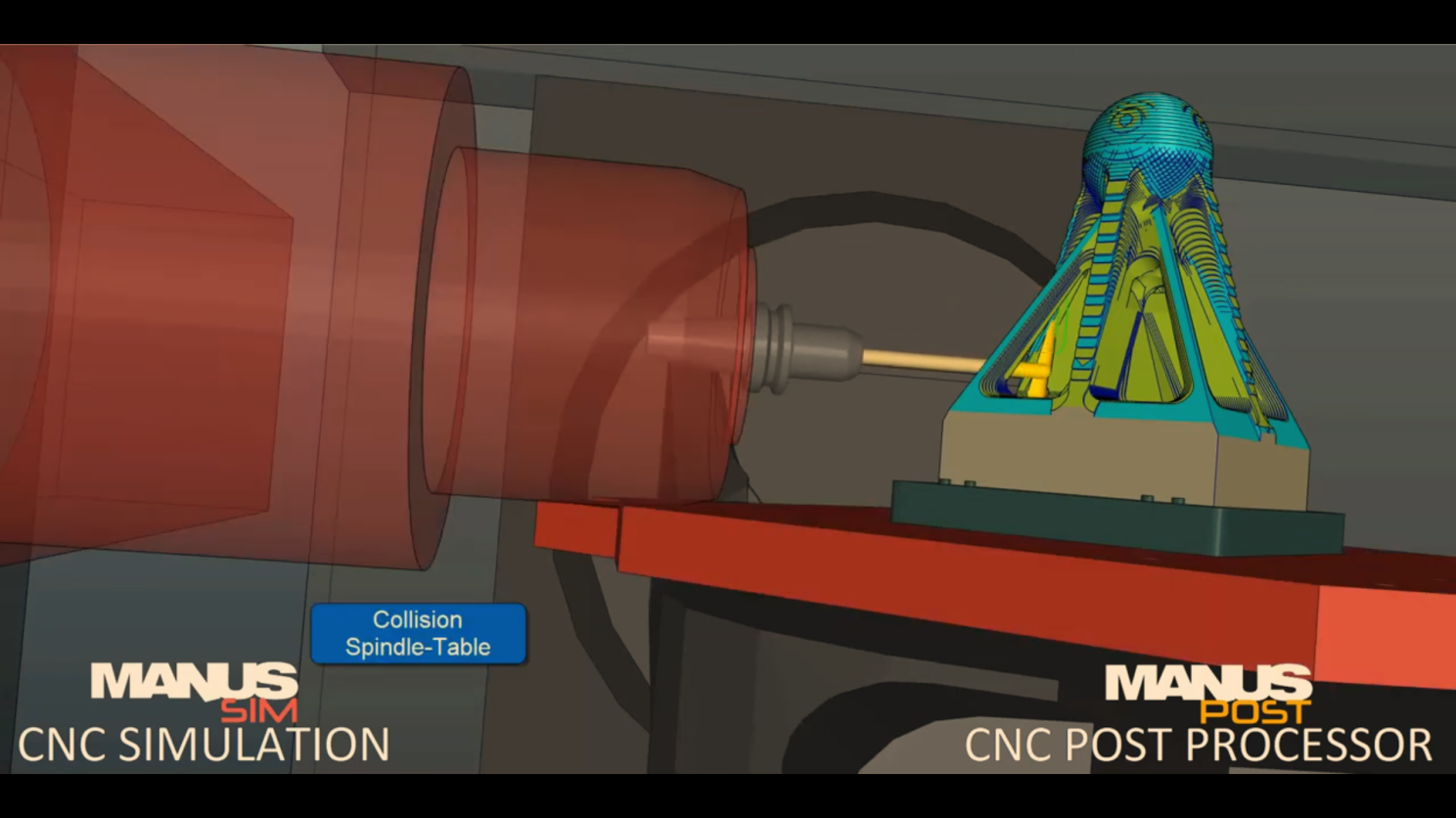

At MANUS, we believe progress starts with visibility. True simulation means verifying actual G-code, exactly as the machine will read it — not just trusting what the CAM software predicts. This helps catch:

🛑 Collisions

⚠️ Axis limit violations

❌ Feed and speed errors

🧰 Tool behavior issues

Before they ever reach the machine.

It’s not just about safety. It’s about efficiency, accountability, and future-proofing your processes.

If you’re still on the fence about G-code simulation, ask yourself: Can your current system really afford the next mistake?

Ready to see the difference for yourself? Let’s talk.

#MANUSsim: https://www.manusnc.com/en/manussim