Everywhere you look, someone’s talking about Digital Transformation.

It’s on stage at every conference. It headlines every brochure. It’s embedded in every sales pitch.

But let’s be honest for a moment: How many companies actually know what it means—beyond the buzzwords?

When you dig deeper into what’s being called “digital transformation,” here’s what you’ll often find:

A sleek new CAD/CAM interface

A full-scale digital twin of the factory (great in theory, vague in practice)

VR headsets that let you “look around” — at what, exactly?

“AI-powered” tools that struggle to prove their worth on the shop floor

Robotic arms (nothing new — they’ve been around for decades)

Additive manufacturing units collecting dust in the prototyping room

In other words: a lot of flash, very little function.

We’re Talking About Jet Engines— But is the back of the plane still made of wood and fabric?

This is the reality in many manufacturing environments today.

The front end looks impressive:

✔️ CNC machines

✔️ AI integration

✔️ Digital twins

✔️ High-end CAD/CAM platforms

But step into the back end, and what do you see?

CNC post-processors that haven’t been touched since the 90s

Manually edited G-code that’s prone to human error

Simulations that stop short of using real G-code

Zero optimization for cutting conditions or toolpaths

MES systems? Often replaced by spreadsheets or even paper checklists

The Boss Feels Confident… Because the dashboard looks modern. But a plane is a single unit. If the back drags, the whole plane slows down.

Just because your CAD interface got a facelift doesn’t mean your production line is digitally transformed.

🛠 Real Digital Transformation Looks Like This:

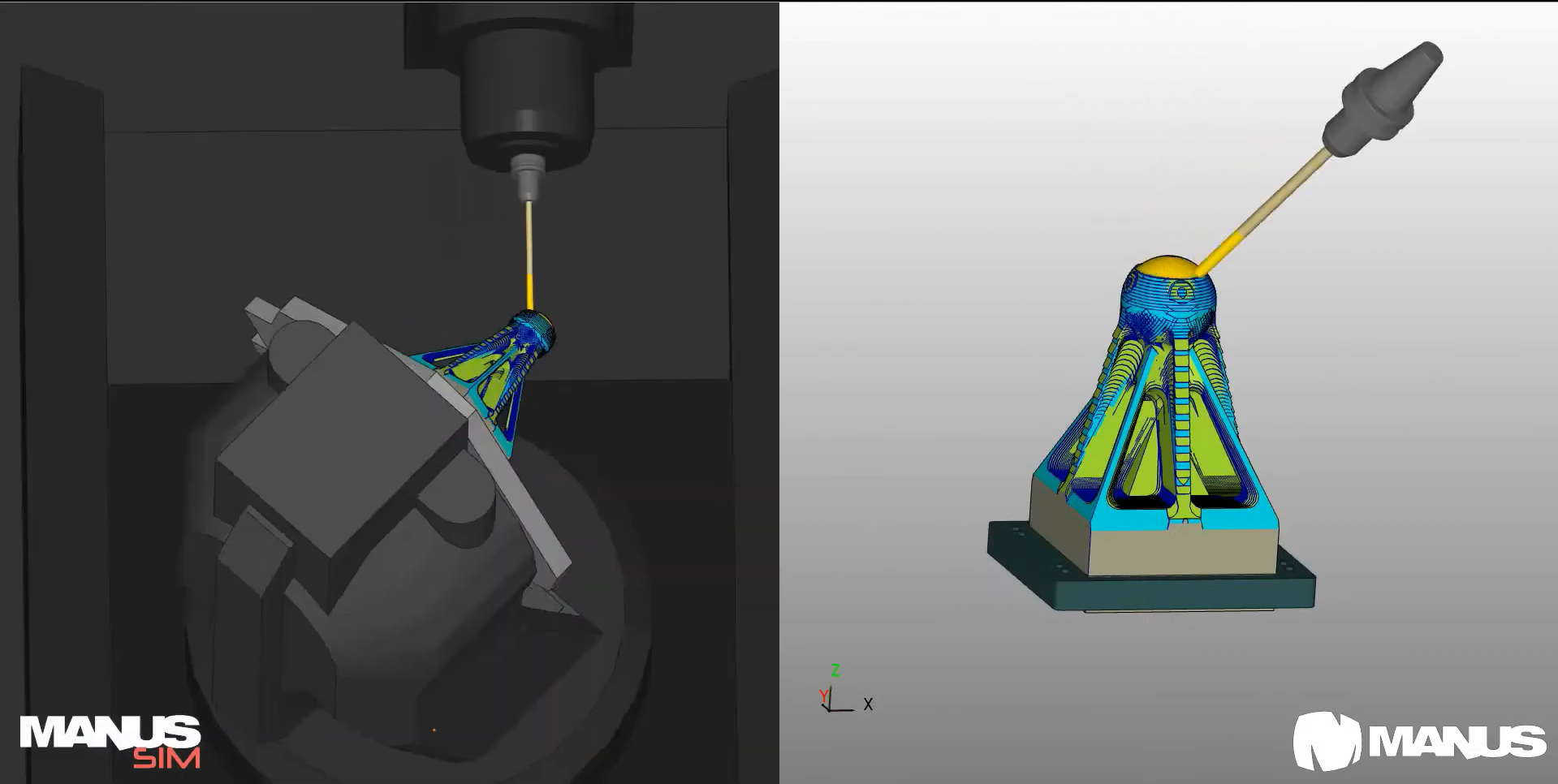

Simulating real G-code — not just toolpaths

Automatically detecting and preventing errors before they hit the shop floor

Optimizing cutting strategies based on real machining logic, not just theoretical models

Using intelligent post-processing tools that adapt across CAM platforms

Integrating MES systems that replace tribal knowledge with real-time data